SANDWICH PANELS

Special aluminium clips have to be used for joining the Kalzip® profiled sheets with the substructure of the roof. They are locked into the seam and will be overlapped by the following Kalzip® element, so that the fixing elements are hidden under the roofing. This ensures that the roofing elements need not to be punctured for fastening.

The newly developed E clip even improves the as such excellent sliding properties of the Kalzip® roofing.

The Kalzip advanced E clip is a steel reinforced GFRP clip that is available in 20 mm height increments, up to a maximum of 180 mm

Kalzip® meets current-day requirements in a special way: • Lightweight • Great strength • Resistance • Corrosion-proof • Practically maintenance-free • Resistant to atmospheric effects • Flexible shape • Non combustible • Can be used as lightning conductor • Can be re-usable • High quality material • Can be recycled • Can be re-used, maintaining full functional quality

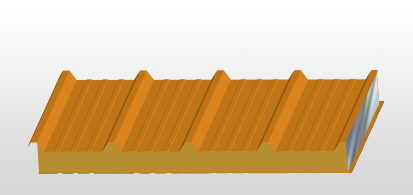

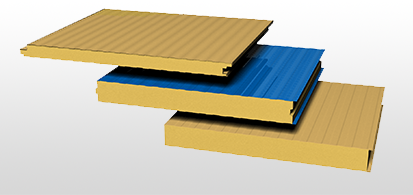

Middle East Insulation manufactures roof and wall sandwich panels by use of PUR, PIR and Phenol with external and internal sheets of steel ALu Zinc or Aluminum of different thickness, coating and colors

The major features of MEI Composite panels are :

- High standards of thermal insulation.

- Provides durability and long life.

- Lightweight and easy installation.

- Saves construction and maintenance cost.

- Full technical and installation support.

- Major saving in energy cost.

Structure:

Free from CFC/HCFC mean no effect on Ozone Layer

Certifications:

Middle East Insulation LLC has a certificate from Dubai Municipality, Please click here

Middle East Insulation LLC has been certified by Dubai Central laboratory for PUR and PIR Insulation foam, Please follow the link click here

Types:

MEI sandwich panels are mainly available in 5 profiles as stated below. For more information on the profiles please follow the links.